The Environmental Benefits of Wholesale Ready to Press Heat Transfers

The fashion industry places greater priority on sustainability in its practices today. Businesses throughout the market seek solutions that minimize their waste production while reducing environmental effects. The wholesale ready to press heat transfers process provides sustainable printing alternatives to traditional printing methods. The production method enables businesses to conserve resources while decreasing toxic chemical usage and boosting energy effectiveness.

Reducing Waste with Wholesale Ready to Press Heat Transfers

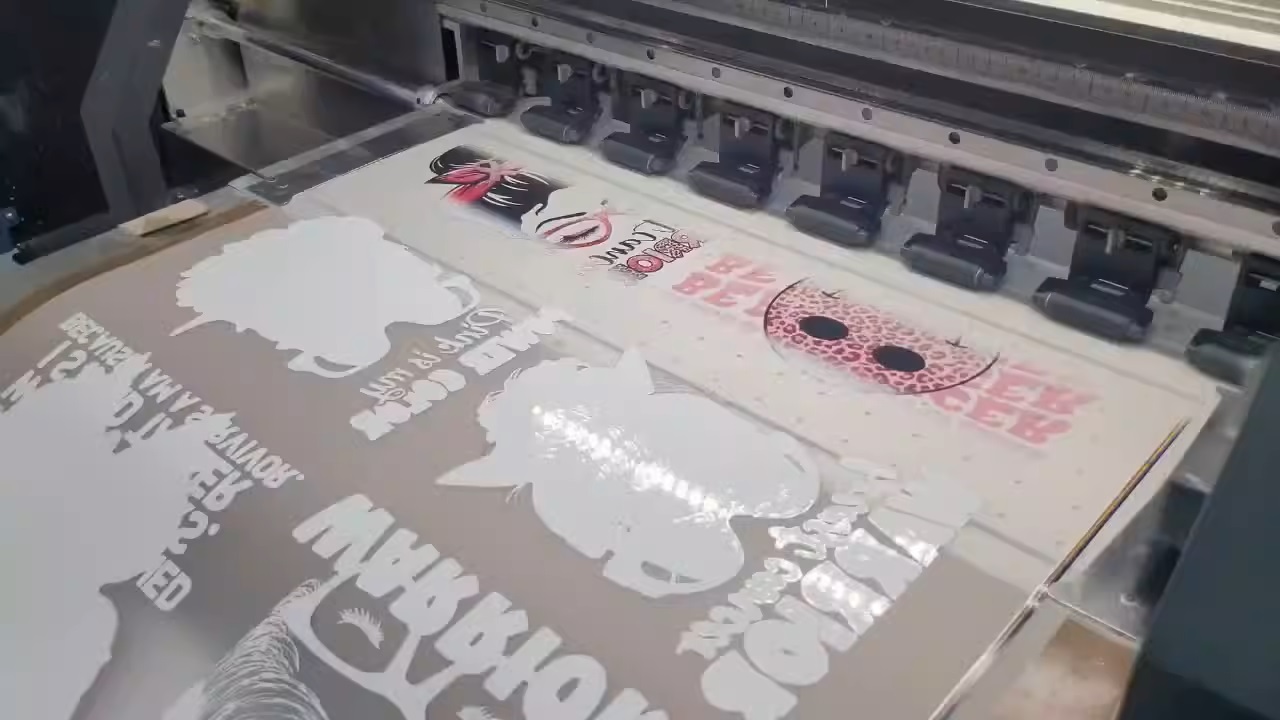

Screen printing operations demand large quantities of ink, water, and various other materials as part of their usual process. Designs that are both mistaken during printing or left unused result in producing unwanted waste. The ready to press heat transfers eliminate waste because they produce only the required number of designs. The process avoids ink mixing together with large screens because it produces small waste amounts that typically end up in landfills. These transfer systems provide businesses with the advantage of real-time digital printing abilities. Companies generate profits by manufacturing shirts only when needed because producing too many leads to inventory loss. The inventory control system lowers stock levels while stopping numerous unsold items from becoming waste.

Lowering Chemical Use in Wholesale Ready to Press Heat Transfers

The environmental damage comes from screen printing due to the combination of solvents and plastisol inks used in the process. The chemicals involved with printing need specific handling procedures because they produce toxic emissions. The manufacturing process of wholesale ready to press heat transfers incorporates a smaller number of dangerous products than other methods. The production process includes pre-printed design sheets on transfer materials, so users do not need to perform any chemical mixing or washing procedures. The production of heat transfer materials includes eco-friendly ink as one of its components. The adoption of water-based and non-toxic inks within this printing technique is increasing, thus promoting safe conditions for workers and preserving environmental health. The market provides biodegradable transfer films as suppliers work towards lowering pollution levels.

Saving Energy with Wholesale Ready to Press Heat Transfers

The screen printing process has several stages to perform, starting from setting up screens before proceeding to ink drying and finally cleaning all equipment. The production process demands significant amounts of power, particularly during operations that use large printing machines. The production process becomes more efficient through ready to press heat transfers because they use heat presses, which need less power to operate effectively. The rapid working speed of heat transfers allows businesses to minimize their production run times. Businesses can now run designs for several seconds and proceed to their next order because of this new production method. The quick production time helps lower electricity usage which leads to a reduction of total carbon emissions in apparel manufacturing.

Conclusion

The fashion and printing business sectors view sustainability as an escalating priority. The wholesale ready to press heat transfers system operates as an eco-friendly production method through minimized waste generation and reduced chemical requirements along with decreased power consumption. The transition to this approach enables companies to reduce their environmental impact through high-quality production. Heat transfers continue to appeal to businesses that want to implement environmentally friendly procedures because of their multiple advantages.